The hum of our machines, the very heartbeat of our digital lives, has been struggling to find its rhythm. We, the builders, the creators, the tinkerers who bring our digital dreams to life, have been navigating a choppy sea of component scarcity. For some time now, a silent but potent force has been disrupting our carefully planned computer builds: a global shortage impacting memory production. This isn’t just about a few RAM sticks being out of stock; it’s a ripple effect that touches everything from the everyday user upgrading their rig to the professional content creator pushing the boundaries of their workstation, and the gamer seeking that competitive edge. We are feeling the squeeze, experiencing firsthand how the intricate web of global supply chains can directly hold back our enthusiasm and our progress.

Random Access Memory, or RAM, is the computer’s short-term memory. Think of it as the workbench where our computer’s processor does its most immediate work. The more RAM we have, the larger and more complex the projects we can have spread out on that workbench simultaneously without slowing down. It holds the instructions for the programs we’re running and the data they’re actively using. Without sufficient RAM, even the most powerful processor will find itself waiting, idle, as it juggles limited space. Discover the future of broadcasting with Fully automated television production that revolutionizes content creation.

How RAM Works: A Deeper Dive

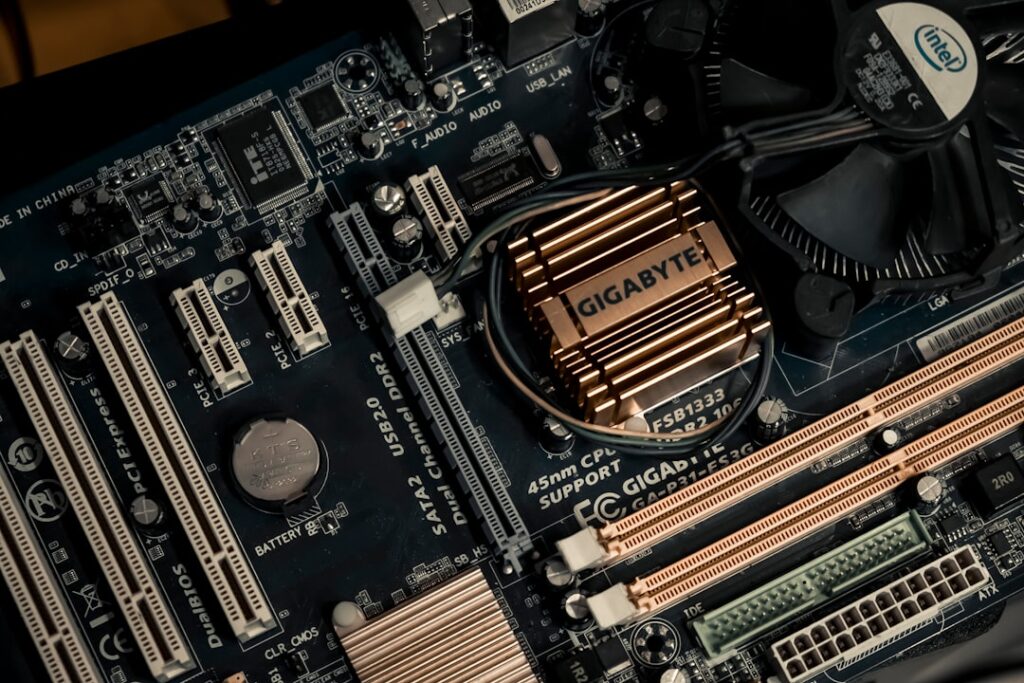

At its core, RAM is made up of integrated circuits, specifically dynamic random-access memory (DRAM) chips. These chips store data as electrical charges in tiny capacitors. When a computer’s CPU needs to access data, it sends a request to the RAM. The RAM quickly retrieves the requested data and sends it back to the CPU. This process is incredibly fast, which is why RAM is termed “random access.” The “dynamic” aspect refers to the fact that the charges in the capacitors need to be refreshed periodically, or they will leak away, causing data loss. This constant refreshing is managed by a memory controller, often integrated into the CPU or motherboard.

The Different Flavors of RAM: DDR Generations and Speed

We’ve all seen the labels: DDR3, DDR4, and increasingly, DDR5. These designations represent different generations of DRAM technology. Each new generation typically offers increased bandwidth (the rate at which data can be transferred), improved power efficiency, and higher clock speeds. Clock speed, measured in megahertz (MHz), dictates how many cycles per second the RAM can perform its operations. Higher clock speeds generally translate to faster performance, especially in demanding applications. It’s akin to having a faster conveyor belt for your data.

Beyond Capacity: Latency and Bandwidth

While capacity (measured in gigabytes, GB) is often the headline feature, latency also plays a significant role. Latency, measured in nanoseconds (ns) or as CAS (Column Address Strobe) latency timings (which are numbers like 16-18-18-38), refers to the delay between when a command is issued to the memory controller and when the actual data transfer begins. Lower latency means a quicker response time. Bandwidth, as mentioned earlier, is the total amount of data that can be transferred per unit of time. A system might have fast RAM in terms of clock speed, but if its bandwidth is limited, it can still bottleneck performance. Balancing capacity, speed, and latency is the art of selecting the right RAM for our build.

The ongoing memory production shortage has significantly impacted computer builds, leading to increased prices and limited availability of essential components. This situation has forced both enthusiasts and casual users to reconsider their upgrade plans and explore alternative solutions. For a deeper understanding of how supply chain issues are affecting technology, you can read a related article on the topic at AITV Media.

The Global Memory Production Pipeline: A Complex Symphony

Producing memory chips is a monumental undertaking, involving highly specialized facilities, intricate chemical processes, and a global supply chain that would make an octopus jealous. It’s not something that can be scaled up or down overnight like flipping a switch.

The Foundry Factor: Where the Magic Happens

The actual manufacturing of DRAM chips takes place in highly sophisticated semiconductor fabrication plants, or “fabs.” These facilities are incredibly expensive to build and operate, requiring billions of dollars in investment. They operate in extremely clean environments to prevent even microscopic dust particles from contaminating the silicon wafers. The process involves photolithography, etching, doping, and deposition – a series of incredibly precise steps to create the microscopic circuitry of the memory chips. The yield of good chips from each wafer is critical to profitability and production volume.

The Raw Material Relay: From Silicon to Chip

The journey begins with raw materials, predominantly silicon, which is purified to an almost atomic level. Other materials like copper, gold, and various chemicals are also essential. These materials are transported to the fabs, where they undergo their transformation. The global nature of this supply chain means that disruptions at any single point – be it mining, refining, or chemical production – can have cascading effects.

The Assembly and Testing Gauntlet

Once the DRAM chips are manufactured on the wafers, they are diced into individual dies and then assembled onto circuit boards along with other components. This stage also involves rigorous testing to ensure each module functions correctly and meets performance specifications. Faulty modules are discarded, impacting the overall output.

The Perfect Storm: Triggers Behind the Memory Shortage

The current memory production shortage isn’t a single-factor event; it’s a confluence of several critical issues that have converged to create a perfect storm.

Geopolitical Tremors and Supply Chain Vulnerabilities

Global events, from trade disputes to regional conflicts, can send shockwaves through supply chains. Restrictions on the export of certain materials or technologies, or political instability in key manufacturing regions, can directly impede production. The interconnectedness of the world means that a localized issue can quickly escalate into a global concern, impacting the availability of the fundamental building blocks of our computer components.

Increased Demand: The Insatiable Appetite for Computing Power

The digital world is expanding at an unprecedented rate. The rise of remote work, online education, cloud computing, and the ever-increasing complexity of software applications have all fueled a surge in demand for computing power. Gamers are pushing for higher frame rates and more immersive experiences, content creators are demanding faster rendering times, and data centers are expanding to handle the ever-growing digital footprint of humanity. This increased demand strains existing production capacities. It’s like a popular restaurant suddenly finding its kitchen capacity overwhelmed by a sudden influx of diners.

Natural Disasters and Unforeseen Events

Mother Nature, as we know, can be an unpredictable force. Floods, fires, earthquakes, or even severe weather events can disrupt production facilities in affected regions. A major flood at a key fab, for instance, can take months, if not years, to repair and bring back online, leading to significant production downtime and a backlog of orders. Similarly, widespread power outages can halt assembly lines.

The Chipmaking Bottleneck: A Production Capacity Constraint

Building new semiconductor fabrication plants is an incredibly long and expensive process, often taking several years from conception to full production. The existing capacity for DRAM production, while substantial, has struggled to keep pace with the exponential growth in demand. This means that even when demand is high, the actual physical ability to produce more chips is limited by the number and capacity of operating fabs. It’s a bottleneck in the system that cannot be easily bypassed.

Navigating the Choppy Waters: Impact on Computer Builds

For us, the DIY builders and enthusiasts, the memory shortage has transformed what was once a straightforward component selection into a strategic game of patience and compromise.

The Price of RAM: Inflationary Pressures and Budget Blowouts

The most immediate and noticeable impact is on price. Reduced supply and increased demand inevitably lead to higher prices. What was once a reasonable budget for a quality RAM kit can now be significantly inflated. This can force us to make difficult choices: do we compromise on capacity, settling for less RAM than ideal to stay within budget? Do we opt for slower timings? Or do we postpone our build entirely, waiting for prices to stabilize? This price increase can effectively act as an invisible tax on our hobby and professional needs, pinching our wallets.

Availability Woes: The Hunt for the Right Sticks

Beyond price, sheer availability becomes a significant hurdle. Popular memory configurations, especially those offering a good balance of speed and capacity, can be perpetually out of stock. We find ourselves constantly refreshing online retailers, setting up stock alerts, and scouring forums for any indication of incoming inventory. It’s a frustrating treasure hunt where the treasure is often just out of reach.

Compromised Performance: Settling for Less Than Ideal

When faced with limited options, we may be forced to settle for RAM that is not ideal for our specific needs. This could mean choosing modules with lower clock speeds, looser timings, or even reduced capacity. While these components might still function, they can lead to a noticeable dip in overall system performance, particularly in memory-intensive applications. The carefully curated balance of our build is disrupted, and we might not achieve the performance we originally envisioned.

The Ripple Effect: Impacting Other Components

The memory shortage doesn’t exist in a vacuum; it has a ripple effect that can impact the availability and pricing of other components. Graphics cards, for instance, also utilize memory (VRAM), and while the shortage is primarily focused on DRAM for system RAM, it highlights the broader vulnerabilities in semiconductor manufacturing. Furthermore, a delay in obtaining RAM can effectively put other components we’ve purchased for a build on hold, creating a domino effect of frustration.

The ongoing memory production shortage has significantly impacted computer builds, making it increasingly challenging for enthusiasts and professionals alike to source the necessary components for their systems. This situation has led to rising prices and longer wait times, prompting many to seek alternative solutions or consider upgrading existing hardware instead. For those interested in understanding the broader implications of supply chain issues in the tech industry, a related article explores the intersection of AI and technology, shedding light on how advancements in AI image generation could potentially influence future hardware demands. You can read more about this topic in the article here.

Looking Ahead: Anticipating a Turn in the Tide

While the current situation is challenging, the industry is not static. Efforts are underway to alleviate the shortage, and there are reasons to be cautiously optimistic about the future.

The Long Game: New Fabs and Expanded Capacity

Major semiconductor manufacturers are investing heavily in building new fabrication plants and expanding existing ones. This is a long-term solution, as these projects take years to complete, but it represents a commitment to meeting future demand. These new facilities will bring fresh production capacity online, which should, over time, help to balance supply and demand.

Technological Advancements: Efficiency and Innovation

Continuous research and development in memory technology are also crucial. Innovations in DRAM architecture and manufacturing processes can lead to improved yields and more efficient production. The evolution of DDR5 and the exploration of new memory technologies hold the promise of overcoming current limitations.

Market Dynamics and Demand Moderation

As the global economy adjusts and certain sectors of demand stabilize, we might see a gradual moderation in the insatiable appetite for computing power. While unlikely to disappear entirely, a more balanced demand could allow supply to catch up. Furthermore, as newer technologies like DDR5 become more mainstream, older technologies might see their demand decrease, potentially freeing up some production lines.

Patience is a Virtue: The Builder’s Mantra

For us, the builders and enthusiasts, the prevailing advice remains clear: patience. Understanding the complexities of the memory market and adopting a patient approach can help us navigate these difficult times. Waiting for prices to stabilize, researching alternative options, and planning our builds with flexibility in mind are all strategies that can help us weather this storm. We understand that the digital world doesn’t stand still, and neither will the industry that powers it. We have seen cycles of scarcity before, and we believe that, with time and continued investment, the flow of memory will once again become a steady, predictable river, allowing our digital creations to flow unimpeded. Until then, we continue to adapt, to learn, and to plan, ever eager to get back to the satisfying hum of a completed build.